SUSTAINABILITY

Toyota Social Support Center

Who we are

Toyota Social Support Center (TSSC) was established in 2020 as the window of TDEM to collaborate with external organizations across Asia to help them enhance productivity, maximize available resources, and improve quality and safety, toward Toyota’s larger goal of producing happiness for all. Our contribution builds on the Toyota Production System (TPS) philosophies & our long experiences in the automotive-manufacturing industry.

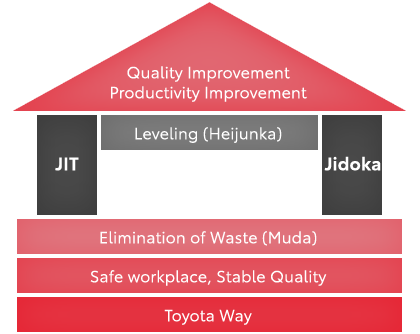

Toyota Production System (TPS)

TPS is our philosophy aiming to create a productive work in both quality and cost perspective, by eliminating waste. It consists of 2 main pillars: Just-in-time (JIT) and Jidoka (Autonomation), founded on the safe workplace & stable quality as per the Toyota Way, which focuses on the continuous improvement & respect for people.

See here for more details.

Creating Smiles in a Hospital in Cambodia

In 2019, Toyota Motor Corporation, TDEM and Toyota (Cambodia) Co., Ltd. launched a project which supported a hospital in Cambodia by utilizing the Toyota Production System (TPS). The hospital achieved significant reduction of patients' waiting time and smoother flow of consultation.

Driving “SMART Hospital” in Bangbo, Samut Prakarn, Thailand

Starting from January 2020, TSSC has been working with the Bangbo Hospital, Samutprakarn, Thailand, toward its “SMART hospital” policy to create a lean operation and enable the hospital to treat a larger number of patients.

Phase 1 & 2 (Jan’20 – Feb’21): Reduce Outpatient’s Waiting Time and Walking Distance

- Shortened lead time in the dispensary system by visualizing and rearranging the workflow process.

- Reduced patients’ waiting time by leveling (heijunka) the slot ratio and rearranging the operation flow to maximize the resource utilization.

Phase 3 (Apr’21 – Jul’21): Reduce Inpatient’s Waiting Time

- Increase the productivity of medical equipment management by eliminating redundant processes and centralizing the whole process.

Build Healthy Happiness in the Neighborhood with Bang Sao Thong Hospital

Bang Sao Thong hospital is a small-sized public hospital of 70-140, on average 92 patients a day. OPD service has limited 2-4 Doctors and 4-6 nurses to service patient queue for doctor & lab treatment.

Fore the before condition, each visit costs the patient about 3-4 hours of waiting time. After leaning the operation with the TPS and rearranging the layout & flow during February – August 2022, the waiting time was reduced by 2-3 hours per visit. This result makes patient happiness, as well as improving the nurse working condition.

TSSC took the TPS concept to aim for simpler, smoother patient flow by following:

- Rearranging the crossing walking routes to a one-smooth flow.

- Adjusting the shortest distance to make efficient queue calling by nurse.

- Creating the 1 guiding-sheet to avoid duplication of asking by each nurse’s processes.

- Fastening the medicine arranging time by feed an online prescription direct from doctors to the pharmacy room.

- Leveling the appointment and balancing the lab time between morning and afternoon.

As the result, Nurses are happier on the less workload and patient appreciated to the new simpler process. TSSC are proud to be a part of community near TDEM and contribute a social support by TPS.

Efficient Inventory System Establishment in the Chakri Naruebodindra Medical Institute

TSSC has been cooperating with the institute since October 2020 to deploy the Just-in-Time (JIT) methodology and establish an efficient, self-reliant inventory system, to deliver appropriate products to user timely, with the minimum required inventory level.

Theme 1 (Jan – Mar’21): Standardization and Abnormality Management

Standardized processes and helped remove abnormalities to reduce backorders and supply shortage.

Theme 2 (Apr – Jun’21): Efficient Inventory through Lead Time Reduction

Reduced overall lead time and inventory by quick, smaller lot ordering, fast purchasing, and product preparation with highly efficient delivery to user.

Moving Forward – Not only internal improvements, but also, the external coverage.

Toward the goal to be the major medical center to serve patience in the eastern part of Thailand, CNMI’s vision does not focus only at the Just-in-time stock management and shorten the internal supply lead time; their vision see more than that.

To further reduce the overall procurement process, exemplar suppliers are selected to create the delivery standard & improve together with the CNMI and TSSC working team. In the end, CNMI can reduce the stock lead time from 17 days to 11.5 days (equal to saving the warehouse space by 53M2 and the holding cost reduction 5 million Baht), which lead to the sunk cost saving and be able to contribute to other patient-related services.

Ramathibodi Hospital in Collaboration for Better.

With the ambition to become a leading medical institute in the world-wide level, Ramathibodi hospital teams up with TSSC to create a fast, lean procurement process with sustainable improvements and customer satisfactions.

As the procurement process is a crucial part in the overall service cycle, Ramathibodi hospital has a great expectation to level up the process, sustain the result, and expand the activity through other functions via the human resource development (HRD) program.

To meet with the HRD goal, Ramathibodi hospital selected 4 members as the key persons to work with TSSC members, learn the PCDA & kaizen cycle, and develop the sustainable improvements with their ideas.

At the end of the project, we could achieve a 40% procurement process lead time reduction (from 94 days to 59 days), and the Ramathibodi key persons still have further ideas to implement onward.

Collaborated with Thammasat University Hospital to Bring Smiles to Pathum Thani Area

With the COVID-19 situation in 2020-2021, there was an urgent requirement to “speed up” the vaccination in the country. Thammasat University hospital (TU) is a big responsible hospital for the Pathum Thani area with the capacity 1,500 persons/day.

Together with TSSC, they aim to create a happiness for people by increasing the “capacity of TU vaccination center” with the LEAN medical personnel process and initiate smooth workflow to “reduce the service lead time”, resulting in the the vaccination waiting time reduction by 54% from 45 to 21 minutes.

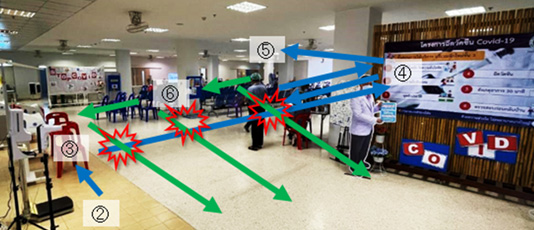

September – October 2021: Gymnasium vaccination center

Utilizing the TPS tools to indicate the bottle necks, adjust the layout, and set up the new process guide, resulting in the smoother flow of customers and reduce the service time from 45 minutes to 31 minutes.

November – December 2021: Hospital vaccination center

As the vaccination demand gradually decreases, the vaccination was relocated to the smaller area. Again, we took another challenging steps by creating the layout plan from zero to shorten more lead time, resulting in a further waiting time reduction from 31 minutes to 21 minutes to get vaccinated.

The West Joins with The East to Fend off COVID-19 Together

In September 2021, Bang-Yai hospital in the western Bangkok joined hands with TSSC from the Eastern Bangkok to help building up the daily vaccination capacity to build up the vaccination ratio to fend off COVID and keep people in the west side of Bangkok safe.

Within a brief month, TSSC and the hospital working team intensively study the service process, build the standard process sequence, and eliminate incidental jobs to reduce the working cycle time.

Then, on the customer’s side, a one-way walking route was created to eliminate the overlapped routes and smoothen the customers flow into the vaccination continuously.

As the result, the vaccination lead time is reduced by 30% from 61 to 42 minutes; escalating the total vaccination capacity by 27% from 498 persons/day to 630 persons/day.

If you are interested in our activities, please feel free to reach out to us for assistance through the below contact:

Email: TDEM_TSSC@tdem.toyota-asia.com

Telephone:

+662-790-6961 Mr. Ake S.

+662-790-6635 Mr. Wittawong P.

For us to better understand your activity and need, please provide the following information:

- Contact person, email, and telephone number

- The name of your organization

- The overview, including mission, of your organization

- Challenges you aim to solve with our assistance

- Another supplement information (if any)